- Sitemap

- Online consultation

Scan WeChat

Scan WeChat

About Us

- Service Hotline -+86-135-2866-9221

Dongguan Huarui Crane Co., Ltd.Since its establishment, after several years of continuous improvement of the manufacturing process, the quality and appearance of the products have been greatly improved. Now the crane series products manufactured have reached the best products in the same industry in Guangdong Province, and have won customers and extensive business. Manager's approval.

1. The steel plates used by our company are from Shaogang, Liugang, Baosteel and other manufacturers, and advanced coil opening and leveling technology is adopted to avoid the defect of joints on the main web of the original crane. There are no welded joints on the main web, which improves the quality, craftsmanship and appearance by a step.

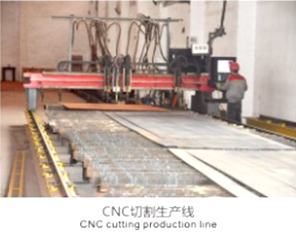

2. After the plate is cut, it is directly cut on the CNC automatic cutting platform. The data such as the camber of the crane itself is input into the CNC automatic cutting machine, and the parameters such as camber are formed at one time, which greatly reduces the error range and increases the accuracy.

3. In order to avoid the deformation of the main beam during the lifting and overturning process, which leads to large errors in parameters, all materials are uniformly cut by CNC automatic cutting machine and assembled on the assembly platform. All cover plates and webs are assembled before the main beam is formed. The crane web reinforcement plate can be hoisted away afterward. Our company adopts angle iron (other manufacturers in the same industry use flat iron reinforcement) to minimize the waviness of the deformation of the web plate during the welding process of the reinforcement plate, which greatly improves the whole crane. quality and aesthetics.

4. After all cranes are assembled and formed on the assembling platform, the main welds are welded by gantry automatic welding to ensure the quality of the welds and also control the deformation of the two main beams (double beam cranes).

5. The end beams and trolleys are made according to Taiwanese and European standards, using conjoined wheels and three-in-one motors, the noise of the crane during operation is reduced to low decibels, and the service life is longer. Its welding and assembly are all in special molds The rack platform is completed, and after the assembly is completed, all carry out no-load trial operation.

6. All parts of the single and double beams produced by our company are assembled on the assembly platform. The assembly platform is measured with an infrared rangefinder to ensure that the horizontal error of all wheels of the crane is within 2mm, and the span parameter error is within 1mm. .

About us

Company ProfileBusiness philosophyManufacturing processCaseVideoOur TeamHonorProducts

Single Girder Overhead...Double girder overhead...Jib CraneGantry CraneCrane AccessoriesQD bridge craneElectric flat carNews

Company newsCrane knowledgeIndustry informationContact us

ContactFeedbackNetworkSales TeamPledgesQuick Contact

Cell phone station

Cell phone station Manager WeChat

Manager WeChatDongguan Huarui Crane Co.,Ltd. Copyright © 2022 All rights reserved Technical Support :Dongguan website construction 【Admin】【Baidu Statistics】【Gmap】【Back to top】

Service Hotline

Miss Yuan

Mobile

Back to top